- Product Details

Keywords

- Oil-field Silicone Anti-foam agent

- Polyether modified polysiloxane

- non-ionic organic silicone surfactant

Quick Details

- ProName: Oil-field Silicone Anti-foam agent

- Appearance: light gray high viscosity fluid

- Application: Oil-field Silicone Anti-foam agent

- DeliveryTime: As order

- PackAge: 25kg, 50kg/plastic drum or as customer...

- Port: Chinese port

- ProductionCapacity: 1 Metric Ton/Week

- Purity: 60%

- Storage: Kept at 5~30 ℃ with good seal

- Transportation: It is non-hazard chemical, it can be t...

- LimitNum: 1 Kilogram

Superiority

1. Fast defoaming, long foam inhibiting effect

2. Perfect dispersibility, simple operation, low usage level.

3. It works normally at high temperature

4. Non-toxic, tasteless, no pollution to environment

5. High defoaming efficiency, improving slurry mud lubricity & cooling effect significantly, increasing slurry mud recycle efficiency greatly

Details

Product name: Oil-field Silicone Anti-foam agent

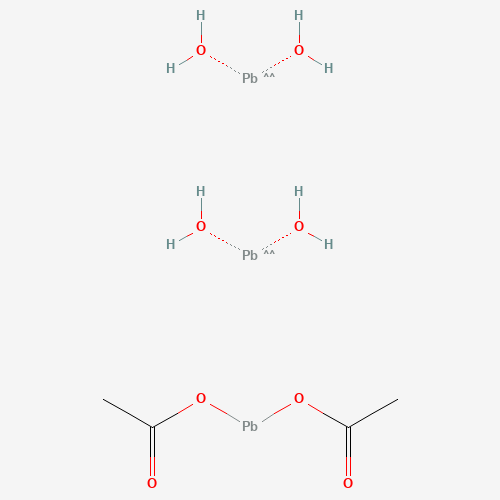

Components

Polyether modified polysiloxane

Physical Technical Index

Appearance: light gray high viscosity fluid

Active ingredients: 60%

PH: neutral

Type: non-ionicganic silicone surfactant

Characteristic

1. Fast defoaming, long foam inhibiting effect

2. Perfect dispersibility, simple operation, low usage level.

3. It works normally at high temperature

4. Non-toxic, tasteless, no pollution to environment

5. High defoaming efficiency, improving slurry mud lubricity & cooling effect significantly, increasing slurry mud recycle efficiency greatly

Properties & Application

- It is new type of silicone polyether graft copolymerization high efficient defoamer, with effective defoaming during well drilling, avoiding bad effect to production.

- Suitable fcontinuing defoaming prohibiting foam activity at the situation of high temperature, acid alkali shear force.

- Excellent heat resistance, acid & alkali resistance chemical stability, widely used fdefoaming inhibiting foam in various harsh system with wide temperature range.

- It is applicable for

a) well-drilling slurry mud

b) Oil & gas separation

c) Transportation of crude oil processed oil

d) Residual oil storage delayed coking

Using method

- It can’t be used in working solution directly due to high active ingredients (up to 60%), it is not beneficial fdispersion, generally, defoamer must be diluted before use,

- Use 20-35’C water foaming liquid as diluent, add required diluent into defoamer while stirring to get 1~5 times evenly dispersed solution, then add solution directly into all kinds of water-based well drilling fluid system to eliminate various kinds of foam, usage level: 0.1-0.5%

- It can be added into well-drilling slurry mud directly as additive, added when slurry mud has foam, to remove foam inhibit foam.

Assessedsupplier

Assessedsupplier